|

Snowmobile Design The McGill Electric Snowmobile Team took a different approach to designing a cleaner snowmobile. Other teams are taking existing snowmobiles and modifying their gas engine and exhaust system to be more efficient. We decided to take an innovative approach and design an electric powered snowmobile. Electric motors are much quieter and cleaner than internal-combustion engines. However, there are many design challenges we have to overcome. Design Challenges Selected Components We are using an e-TORQ DC Brushless motor because of its high torque-to-weight ratio. Also, brushless motors are maintenance free and extremely reliable due to the fact that the phase commutation is achieved by an electric circuit (instead of a conventional brush/commutator system). NGM EVC200 Motor Controller

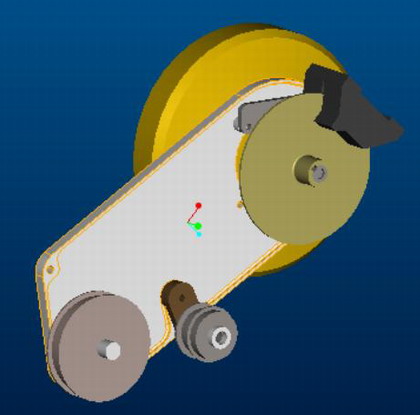

Motor and Brake Assembly

|